Product Regulatory Compliance: Definition and Scope

By Tom Killam and Cyril Mecwan

April 18, 2021 | Series 1 / No. 1

According to the U.S. Consumer Product Safety Commission (CPSC), at least 41 Americans were killed and about 133,000 injured between 2017 and 2019 in incidents tied to e-scooters, e-bikes and hoverboards.1

10 companies were forced to recall approximately 500,000 hoverboards after CPSC received about 100 reports of the lithium-ion battery packs that power hoverboards overheating, sparking, smoking, catching fire or exploding.2

The importance of the Product Regulatory Compliance could not be stressed enough. While the above example is a very small segment of concern, its occurrence brought light to a serious shortfall in the space.

Background:

The business landscape in any state or country world over is full of regulations. Environmental, Energy, Health, Education, Legal, HR, Finance, Corporate Governance etc. – there are many regulatory compliances in place for these and many more functions at large. Similarly, there is regulatory compliance in place to regulate the products that are marketed in a country – such compliance is called Product Regulatory Compliance. Additionally, Product Regulatory Compliance involves regulations of end products, components, materials, systems, and processes.

Definition:

Product Regulatory Compliance is the process of testing, certifying, and receiving approval that an end product meets mandated industry standards for relevant requirements in a particular industry and market. Typically, these requirements apply to products that utilize modern electronics, however, some product regulatory requirements are applicable to various health, environmental and safety concerns for food & grain types, drugs, oils, chemicals, fabrics, cosmetics etc.

An Original Equipment Manufacturer (OEM) is obligated to test its products to determine conformance to the applicable standards mandated by the regulatory authority of a country, followed by obtaining an approval prior to shipping the product to that market. A copy of the approval is generally required to accompany the product when shipped.

Product Regulatory Compliance is obtained at a product or SKU (Stock Keeping Unit) level and generally the approval marking must appear on the product. Sometimes, it is also applicable to critical components or spares that accompany the product. Generally speaking, the component level regulations are managed by the component supplier, however, sometimes the test data from the approval is rolled up to the end product level and declared to be in compliance.

Relevant requirements vary based on a country, industry, and technology. The requirements may include, but not limited to, Product Safety, Electromagnetic Compatibility, Radio, Telecommunications, Energy Efficiency, Environmental, Quality, Performance etc. Further, these technical requirements can vary from country to country and when combined, form the rules for global regulatory compliance.

Additionally, voluntary, technology-specific certifications are offered by various Special Interest Groups (SIG) and alliances such as, but not limited to, Bluetooth, Wi-Fi Alliance, USB, Zigbee Alliance, DLNA, 80 PLUS, Dolby, HDMI, LoRA Alliance, MoCA, OTA etc. Typically, these functional approvals allow the use of the consortium's identification logo to appear on the product, packaging, and marketing literature.

Moreover, many government agencies, aviation and military may require performance and quality standards that must be met. Some of these are uniquely specialized and peripheral requirements, which may not fall within the typical definition of the Product Regulatory Compliance. And yet, from standpoint of business, economic or safety considerations, the requirements of these specifiers must be taken care of. For example, "The U.S. Internal Revenue Service released Notice 2015-4 which specifies the performance and quality standards that small wind turbines must meet in order to qualify for the 30% investment tax credit and which requires that small wind turbine models be certified ……"3

Furthermore, consumer and enterprise products requiring the use of the mobile phone carriers and telecommunications network access may have to comply with the requirements developed by Telcordia, a Telecommunications Standards body. In addition to the Telcordia requirements, many times carrier-specific requirements will be imposed from the likes of Verizon, AT&T, T-Mobile, Vodafone, Orange, Telstra etc. Typically, collaborating with the network providers to conduct tests and satisfy such requirements also become the responsibility of the compliance engineers.

Lastly, large e-commerce distributors may have their own requirements that might be more stringent than the country's regulatory requirements.

Scope:

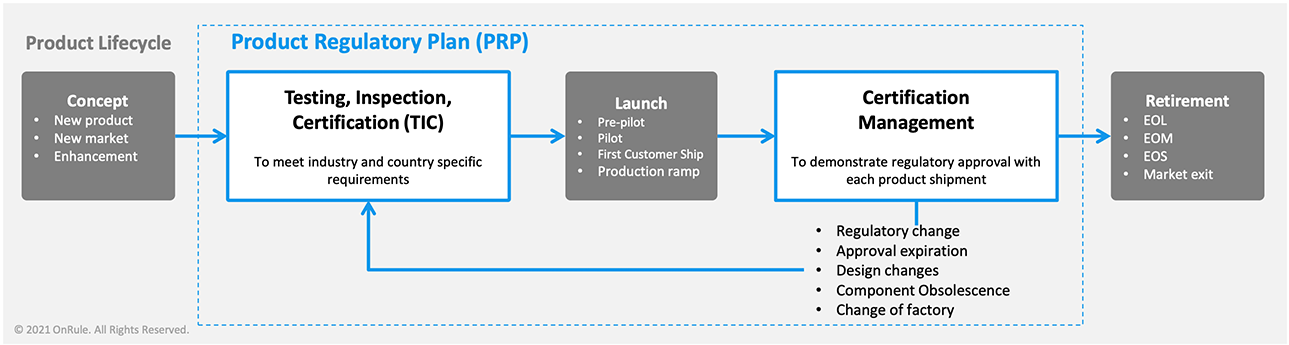

For the entire product lifecycle (from concept to retirement), and for the entire value chain (from critical components suppliers to the end customers), the function of Product Regulatory Compliance touches them all. It is an important and omnipresent function impacting all other functions and stages.

- Concept to Launch: In the new product introduction (NPI) phase, a product design is validated for the Product Regulatory Compliance through the testing process. The design related issues, weaknesses, and bugs identified during the testing of early prototypes are incorporated into the next iteration of the product design to make the product robust and compliant. The final testing of the product is conducted to produce the final test reports, which in turn are used to obtain the approval from the product regulatory authority. At this point in time, the product is ready for a General Availability (GA) and for a release in the core market(s) where approvals have already been granted.

- Launch to Retirement: Once the product is released in production, it enters the sustaining mode. To further proliferate the sales of the product to new markets, wider Global Market Access (GMA) is acquired through fulfilling the testing and certification needs of additional countries. In this phase, certification management of existing product portfolio becomes critically important. Many different events during the sustaining phase call for revisiting the testing & certification; these important events include, but not limited to:

- Change in the underlying standards in a country for a discipline may require retesting of the product to the new or revised standard resulting into a new approval.

- Not all countries give a product regulatory approval for life. Some certificates require renewal from one to five years from the original approval date.

- Any major change in an existing product design may require revisiting the testing & certification.

- A change in a critical component, such as a power supply, requires a revisit of testing & certification.

- Lastly, some regulatory authorities require follow-up visits to the factory for inspection to determine that the product has not changed. If the original factory has changed, it is necessary to disclose the new factory, and may require testing & certification to be revisited.

As mentioned earlier, the Product Regulatory Compliance is demonstrated at the product or stock-keeping unit (SKU) level. However, the OEM is required to disclose the list of critical components used in the final product. As part of the overall evaluation of the end product, some regulatory authorities even require proof of safety certifications from the component suppliers. If a critical component has more than one approved sources (which typically is the case for the purpose of managing the supply chain risk), the proof of safety approval from all sources must be submitted.

Reference:

- https://www.cbsnews.com/news/e-scooter-hoverboard-e-bike-deaths-41-last-3-years/ by Kate Gibson, September 17, 2020, CBS News, Moneywatch

- https://www.cpsc.gov/Recalls/2016/self-balancing-scooters-hoverboards-recalled-by-10-firms

- https://www.a2la.org/regulators/domestic-recognitions