Conclusion: Technology Revolution, Productivity Gains, and the Last Frontier

By Cyril Mecwan

November 17, 2021 | Series 1 / No. 13

Throughout the first and second waves of the technology revolution that took place in the past thirty-five years, businesses identified and pursued the optimization and automation of the obvious and visible functions and processes, such as, product development, product management, manufacturing & supply chain management, sales, marketing, finance, customer support, etc.

The Product Regulatory Compliance is one of the last enterprise macro processes that remains untouched and is ripe with opportunities to streamline, automate and bring the resultant productivity gains.

Technology Revolution:

In early ‘80s, the semiconductor technology growth fueled by the Moore’s Law unleashed the innovation to miniaturize the footprint of the products while leapfrogging their performance. The Silicon Valley became the epicenter for new businesses, disruptive products, and more jobs. During these times, the productivity improvement gained through the use of innovative Information Technology tools and process improvement remained at the forefront and brought stellar performance and economic gains. The other industries, in turn, invested in the technology tools, driving efficiency improvements and related productivity growth in ‘90s and early ‘2000s. This in turn drove USA’s GDP growth, while also improving the living standards world over through the enablement of globalization.

The first wave of technology revolution, fueled by the Internet age (approximately mid ‘80s to 2000) enabled Integrated Networking coupled with the B2B applications allowed the businesses to optimize and flatten the inter-enterprise macroprocesses, making the business as a whole very productive, reducing the overall cost, improving the time-to-market, and increasing the profits.

In the second wave of technology revolution, termed as the digital age (2001 until now), the use of newer technologies such as cloud computing, big data, and machine learning are further integrating and streamlining the business processes, making them collaborative and real-time, collapsing costs and constraints, and yielding higher benefits and productivity gains. The new breed of products is now augmenting or competing with the products established in the first wave, and further automating them through the implementation of rule-based intelligence.

Productivity Gains:

Reviewing past three to four decades, following are some of the examples of the use of new products and tools employed by different functions within the businesses that helped remove complexity and drive efficiency.

- New Product Development: The science of new product introduction (NPI) was being understood and taking a formal shape. The phases of NPI and gate reviews evolved as a discipline to quickly launch new products at the lower cost and higher quality. The emergence of Electronic Design Automation tools such as Allegro, Fusion, Calibre and Tessent for electrical engineering; ProE, SolidWorks and AutoCAD for mechanical design; Ansys for engineering simulations and FloTherm for conducting electronic thermal analysis helped visionaries and developers give shape and form to their ideas. Agile, SAP and Arena Solutions ruled the roost when it came to the Product Data Management (PDM) and Bill of Materials (BOM) listing the critical components that tells the supply chains what to build and which parts to source. The time it took from developing a concept to producing a prototype drastically reduced. The MS Project brought the project management organization in the ‘90s, whereas during the second half of the evolution, the tools like Asana and Trello brought the required collaboration and visibility. GitLab, Docker, Kubernetes, Jira and many more such tools have been in use in systematically developing a software, managing the software lifecycle, or to track software related projects and issues.

Because of these and many other tools in support of new product development, today, the new product introduction has turned into an efficient innovation engine.

- Manufacturing Operations: On the manufacturing front, what used to be ‘Material Requirements Planning’ (MRP) turned into ‘Manufacturing Resources Planning’ (MRP II), and finally metamorphosed into the ‘Enterprise Resource Planning’ (ERP). A deeper understanding of the flows of the order, inventory, and monies within the business partners and suppliers emerged; a new discipline named ‘Supply Chain Management’ emerged; the graduate and undergraduate programs started to offer the Supply Chain Management as a concentration or a major! The birth and evolution of systems such as Oracle, SAP, Dassault Systemes, etc. in support of the businesses with inhouse or outsourced manufacturing – products, assemblies, subassemblies, and components - connected the global supply chains and brought enormous benefits through optimal planning, ordering, storing the required products and inventories throughout the stages of supply and fulfillment – from the upstream to downstream. The optimization made possible through connecting the Order Management to supply chains removed many uncertainties for sales and customers. The rules-based analytics and automation of planning & forecasting, logistics, facilities, and information brought the benefits of securing lower cost and availability of the product at the right time and right place. The businesses formerly managed using large and multiple spreadsheets can now benefit from the automation brought through the evolving information systems and analytics. Information is now available at one’s fingertips, whereas optimized decisions, guided with algorithms and analytics, are instantly made. The second technology wave introduced many cloud-based companies offering the supply chain solutions, such as, but not limited to, E2Open, Palantir (with its big data analytics), etc.

- Sales: Managing the overall sales process - creating leads, identifying prospects, and engaging with the potential customers to have multiple interactions to understand the customer requirements and pitch the Original Equipment Manufacturer (OEM) products – is critically important for the OEMs. It became imperative that the interactions and information gathered on multiple medias – phone, emails, spreadsheets – be organized and harnessed to make it simple, efficient, and responsive. The Customer Relationship Management (CRM) systems such as Salesforce.com, SugarCRM, Siebel Systems etc. filled this gap. Today’s sales teams cannot be perceived without the use of Salesforce.com! The ability of Sales management to track the stages of sales by geography and products, and create a pipeline with a certain confidence level have been used throughout the organizations: the CEOs use this information to provide the guidance of growth to the investment community; CFOs use it to determine the up and down of the company scale and necessary actions (of hire or hold); the operations leverage it to adjust the inventory levels required throughout the OEM’s supply chain, and so forth.

- Marketing & Product Management: As exemplified by Apple, IBM, Intel and HP, a need for a solid organization behind the glitzy product launch, promotions, and branding campaigns became apparent. Marketing experts creates series of content to educate and align the target market. On the other hand, the Product Management (which could also be a function of marketing), is responsible to manage the overall lifecycle of a product and related activities – from introducing a product to beta customers to managing the releases during the sustenance to gradually phasing out during retirement. From approving a part number to ensure complete product documentation by market, to set up the channels and pricing, and to promote the product in the market, the Marketing is a ubiquitous function requiring crisp management. While the software tools like SAP PLM, Agile, ENOVIA, and Arena PLM provided the organization of the Product Lifecycle Management (PLM), many marketing tools, such as Marketo, HubSpot, Mailchimp, etc. are introduced to organize and automate the marketing activities.

- Finance: Managing the cashflows, conducting the basic operations of keeping the financial reports up to date, conducting procurement activities, managing budgets and many more critically important activities are managed today using the state-of-the-art tools with analytics, formal approval cycles, suggestions, and decision aided algorithms. Oracle and SAP have been used by the large enterprises, whereas small to midsize companies continue to use QuickBooks, Sage, etc. Anaplan is the new, cloud-based software product enabling business planning. Additionally, there are many point solutions available to manage particular areas within finance.

- Customer support and service: As OEMs continue to develop and introduce new products at a fast pace, the after-sales support and services become important aspects to keep the customers happy and fulfill their needs post-sales. A value-based support was categorized into levels, and during the Internet era, the phones were replaced with the web-based tools developed by internal IT departments to extend the support employed by the global support structures. In the digital era, the cloud-based solutions such as ServiceNow, Zendesk, etc. are the new software tools used by the OEM companies to support their customers; the features like live chats and virtual meetings further expanded the user experience – this is one industry which has seen a drastic reduction in the support costs owing to the emergence and adoption of the IT tools.

- Human Resources Management: The early thinkers of the human relationship (and its effects on the productivity) such as Elton Mayo and Abraham Maslow, and the avid practitioner of the people management like Jack Welch would have marveled to see the advancement in the organization of the HR space owing to the technology advancement. Maintaining an employee’s career lifecycle in an organization, goal setting and performance history of an individual, performance reviews, compensation management, health benefits, employee development roadmap and progress, etc. are necessary but painstakingly demanding processes to maintain. The early tools developed by Peoplesoft during the Internet age laid the groundwork of organization and automation of key HR processes, whereas the latter applications released in the Digital age, such as Zenefits, Workspace, SAP SuccessFactors, etc. enabled further intelligence to these processes.

The Last Frontier: Product Regulatory Compliance:

The Product Regulatory Compliance is in place to regulate the products that are marketed and sold in a country. These regulations ensure that many product-specific parameters are in conformance such as, but not limited to, Product Safety, Electromagnetic Compatibility, Radio, Telecommunications, Energy Efficiency, Environmental, Quality, Performance, etc. An OEM is required to test its products to conform to the applicable regulations/standards mandated by the regulatory authority of a country, and then get an approval before it can start marketing the product in that market. A proof of the approval is generally required to be shipped along with the product.

To achieve the product launch dates, it is critical to have timely compliance approvals for all markets where general availability (GA) of a product is planned. The Compliance Manager, Compliance Engineer and Compliance Specialist work closely with the test labs and consultants to obtain the core approval and global market access.

Since a product could not be shipped without having the regulatory approval, many stakeholders – product management, product marketing, engineering, sales, operations, distributors & resellers, etc. - require the proof of the regulatory approval, and are in need for visibility and instant access to the relevant compliance records. It is important to provide the relevant and correct compliance documents to stakeholders for a timely product release and product shipment.

The following minimum capabilities are required to achieve the operational excellence through the superior management of product regulatory compliance, which could be accomplished with the use of a sound software product:

- Project Management: There is a need to streamline and automate the compliance processes to enable collaboration, visibility, and quick decision-making in order to reduce the time to obtain the product regulatory approval and accelerate the 'Time-to-market'. The use of software can enable collaborative communication, bring standardization and scale, expedite the approval process, and maintain the history. Additionally, a software system can offer the knowledge base comprised of compliance intelligence so that the Compliance teams have an upfront understanding of the required compliance deliverables for a product-market mix. Such intelligence will help the Compliance professionals estimate the scope of the compliance testing & approval projects, allowing them to convey the important timelines for approval to the stakeholders. Moreover, it will help in budgeting and allocating resources required to manage the projects.

- Records Management: Organizing the compliance records by important and multiple compliance attributes such as, but not limited to, applicable products, record types, record disciplines, markets, standards tested, etc. helps achieve single source of truth. This prevents multiple copies of the same document in the system, enabling quick search and secured share. These records may be the support documents required by test labs to fully understand the product environment before conducting testing, or collateral required by the approvers to assess prior to granting the approvals, or the final approval documents required to formally release and ship the product to a market. Providing the correct compliance document in the timely manner results into ‘Time-to-revenue’ and ‘On-time shipment’.

- Self-Declarations: With many countries now embracing the self-declaration process, bringing automation to this process will bring simplicity and ease in digitally creating, reviewing, approving, signing, and sharing declarations for disparate markets (EU, UK, US, Australia, Taiwan, etc.). Since Declaration of Conformity (DoC) of different markets vary in formats, content and other requirements, the use of automation will make it easy to generate all the variations without making errors, and share with the stakeholders, while eliminating the hard copies!

- Event Based Management: It is important to have a system in place that provides upfront signals and warnings about upcoming expirations so that the managers could plan the budget and allocate resources for re-certification. Importantly, correct compliance records prevent ‘Stop ship’ and ‘Ship hold’, thus positively contributing to operational excellence!

- Standards Update Notices: Continuously changing technical standards and their impact on the product approvals is a big challenge for the Compliance professionals. It is ideal for the Compliance teams if they automatically receive the notifications of changing standards that also list the impacted products and records! Now the Compliance professionals can quickly assess the changes for the affected products and take the proactive actions.

- Analytics: In this age and time, where the use of data analytics and trends instantly provide the necessary intelligence as a means of making the business decisions, the Compliance managers would like to glance through the Compliance Dashboard that summarizes important parameters of the compliance activities. The list of ‘Ok-to-ship countries’ for a product; the status of a compliance project and its expected completion date; total number of compliance records and the types of records; the number of products with Type Approval Certificates vs. the Self-Declarations; the number of products that are exempted from approval for a market; the number of records expiring in next six months, etc. – availability of all these metrics provide the Compliance manager with proper insights and enable to manage the business at a strategic level.

Today, generic tools like Microsoft SharePoint, Box, Dropbox, Google Docs, Google Smartsheet, etc. have been used primarily to manage the regulatory documents. However, their capabilities in the space of product regulatory compliance are limited in nature. The use of the generic tools does not help streamline and automate the compliance processes. These generic tools lack the compliance intelligence which would otherwise suggest country-specific compliance deliverables for a subject product. Importantly, the repositories do not offer the record types and record disciplines that are specific to regulatory compliance, hence there is no automatic guidance provided to the compliance users. Very important parameters such as regulations and standards related to a product and documents lack the association and tracking capabilities. Quickly searching for a compliance record and sharing with stakeholders is a challenge, too.

Among all important business functions, it seems that Product Regulatory Compliance is the last frontier that yet needs to fully benefit from the technology revolution.

Conclusion:

From new product introduction to manufacturing, from order to shipment, and from sales to services – one by one, the enterprises started to break the functional constraints by optimizing and automating the business-critical processes. As these constraints were broken to achieve the productivity gains, new constraints are now coming to the forefront. We are now at a stage where the Product Regulatory Compliance is becoming visible as an area of opportunity requiring optimization and automation that can realize sizeable and incremental productivity gains and help businesses continue their march for excellence.

Reference:

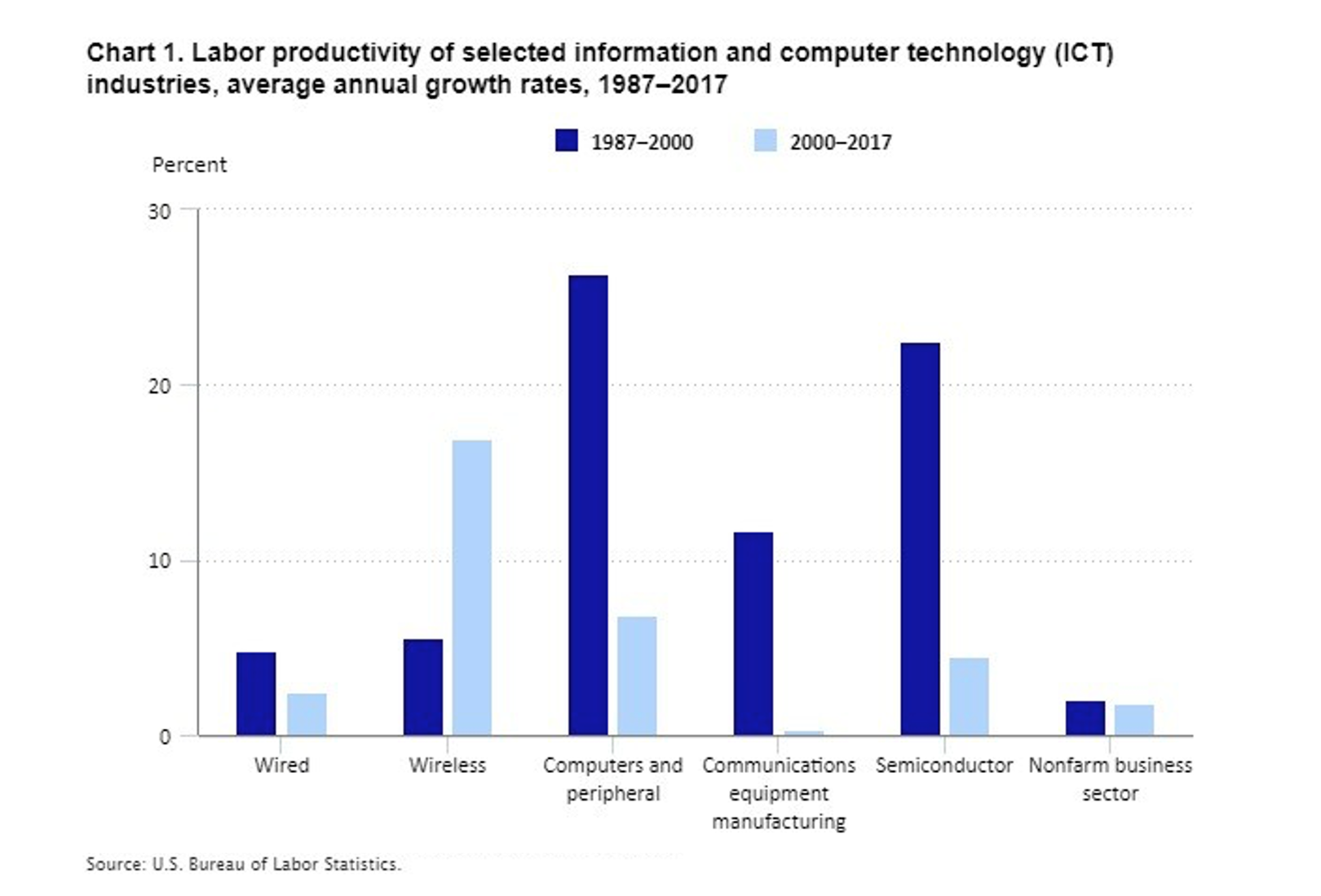

- Chart: U.S. Bureau of Labor Statistics: https://www.bls.gov/opub/btn/volume-8/productivity-trends-in-the-wired-and-wireless-telecommunications-industries.htm